Electrical panels are systems made in various phases, where the first, essentially, is the design, the second is assembly and the third is the wiring of industrial electrical panels.

Let’s quickly recap the first two:

-

- The designing of the electric panel is the ‘design’ phase, that of the technical design of the system, which is carried out with specific software.

Of course, this phase is done following an agreement with the customer, during which we understand their specific needs in their everyday workplace; (in this article we talked about the design of industrial electric panels and the documents at the base of the work);

- The designing of the electric panel is the ‘design’ phase, that of the technical design of the system, which is carried out with specific software.

-

- The assembly of electrical panels, phase in which the various components of the panels are assembled together, following the technical design (in this article we talked about the assembly division and about the components of industrial electrical panels)

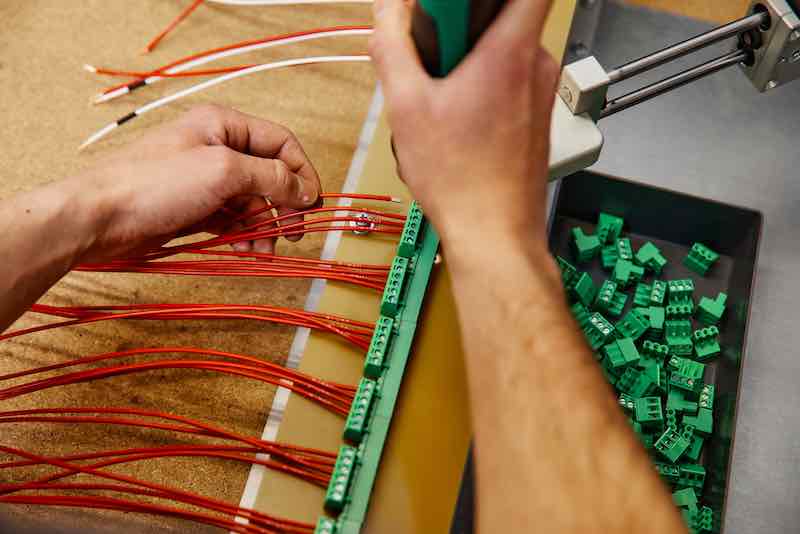

The workers then pass on to the wiring, the third phase in the manufacture of the electrical panels, when the cables are ‘fastened’ or rather ‘connected’ in order that the electricity is transmitted and the panel works to perfection.

What is the wiring word? And what laws regulate them?

The modern design must reconcile the needs of the customer with the current legislations.

The cable connections, which are the result of the indications contained in the technical designs, must, essentially, make the system work. However they must also make sure that the functioning is safe for everyone, from the workers to the environment where the work is done.

Only when there is functionality and safety can the electrical panel ‘serve’ the company and be safe for everyone. This is why there are specific regulations connected to the wiring of industrial electrical panels, like in the manufacture of the system in itself.

We must remember that the regulations connected to industrial electrical panels are essential both to have guidelines and to guarantee everyone’s safety.

Basically, the regulations on wiring which are fundamental to be able to proceed with the CE marking are:

- 2006/95/CE – Low Voltage Directive : regards electric material destined to be used within certain limits of tension and covers the health and safety risks which come from the use of electronic devices with a tension of between 50 and 1000 V on alternating current and between 75 and 1500 V on direct current.

- 2004/108/CE –Electromagnetic Compatibility Directive: this Directive deals with a precise situation: a large number of the machines which enter into the Low Tension Directive in terms of field of application can generate some interference between, which could compromise or influence their smooth functioning. The Electromagnetic Compatibility Directive has, therefore, the aim to ensure that any eventual electromagnetic disturbance produced by the panels do not affect the correct working of the other devices in use.

The quality of the single components

Every single component of the electrical panels must be of high quality, because this guarantees efficiency and a long life of the system over the course of time.

For this reason, apart from a choice of selected suppliers, we have decided to stock up our warehouse with a rich supply, also of those components which are difficult to find, in order to be able to assembly and wire quality panels under every point of view.

A clear and functional wiring of industrial electrical panels

To the high quality of every single component of the electrical panels, another fundamental aspect is added for the system to be manufactured to perfection.

Some speak of electrical panels as real life ‘works of art’ because they are effectively composed of different elements, which have different shapes and colours.

Joined together, through the wiring, these elements give life to a further work, which apart from being functional, in our opinion must also be clear and organised.

Order and clarity are, in fact, what guarantees an efficient functionality of electrical panels, but also a characteristic which – eventually – permits the carrying out of maintenance which is just as clear and organised over the course of time.

Order, clarity and quality are therefore objectives which we aim to achieve in our work, since it permits us to make efficient, functional and safe systems.

For any information regarding our services of manufacturing electrical panels, we invite you to contact us here.